Home Farm Nacton - the farm

In the last three decades the business has been shaped by a high level of investment in water management and irrigation, removing a constraint which once limited production to potatoes, carrots, sugar beet and cereals with limited yields and returns. The majority of our farmed area is light land which can be worked year round, the downside being that without irrigation it was difficult to compete in terms of producing mainstream crops. With the capability to irrigate 98 per cent of our farmed area we focus on high-value crops, mainly early-season crops which are harvested from May to July and are followed by winter-harvested second crops. Potentially, we are planting and harvesting crops every day of the year so we work the land hard, but as our focus is on farming sustainably we enhance the soil’s status by returning manures, compost and cover crops.

Home Farm Nacton location

Home Farm is situated in The Street, Nacton; the office is a portion of Camilla court. Behind Camilla Court there is a coldstore where direct sales are collected and lorries are loaded. Beyond this there are crop stores, workshops, and machinery stores. There is also a second yard at Felixstowe Road which has an extensive concrete area with a large onion drying and storage facility. We also have other farm buildings and yards at some of our farm contract partners’ facilities.

The history of Home Farm Nacton

In 1962 George Pretyman made over the estate into a trust and he kept the farm as a separate operation. He went into partnership with his daughter, Gillian Bence-Jones, who is now our senior share holder. Gillian went to agricultural college and was very interested in new approaches and ways to enhance poor, light mainly arable land. We were still very old fashioned with a dwindling, elderly workforce, Victorian buildings (lovely but not suited to large machinery) and a minimal fleet of small scale tractors. One of the previous farm managers was still riding a horse for work in the 1970’s. Gillian was very keen to invest in irrigation, which was an unusual step for a full scale farm at that time.

George died in 1979 and soon there was a new farm manager at Nacton, young Roger le blanc Smith. Gill and Roger were both keen to try new things but without much capital the farm had to earn its own investment. Gradually we moved into more vegetable production with a working relationship with Marshalls, the wholesale merchant to several of the larger supermarkets. This meant a lot of change and learning for us. Nick Bence-Jones became a partner in the 1980’s and when Roger le blanc Smith left in 1996 he was replaced by Andrew Williams. In the late 1990’s Andrew took us into Organic vegetable production. Since then we have expanded to farm other land on other people’s farms in various contract agreements. Andrew has transformed Home Farm Nacton in size, number of workforce, and intensity of cropping. In 2014 we changed from a partnership to a company and have formed a board of directors.

The people of Home Farm Nacton

The team comprises of people in charge of specialised departments such as spraying, mechanical maintenance and fabrication, skilled machinery operators, muck spreading and general farm workers. The business employs just under 50 regular staff as well as seasonal workers who swell the number to over 100 on a busy day.

With a number of staff in key roles now approaching retirement, training the next generation is key to ensuring the sustainability of the business. Competence with computers and satellite systems is now an essential as well as all the previous machinery operating skills. Says Andrew Williams, ”We have several staff who joined us from school and are now in their twenties and thirties working in key roles such as drilling, spraying, fertiliser spreading, harvesting and maintenance. To ensure that we will have the skills required to maintain a very complex farming system and the equipment needed to operate it we have to encourage, foster and train the next generation. Because we are so diverse we need people who are multi-skilled and can fit into as many roles as possible. Training is a key part of that process."

I have worked for Home Farm Nacton since 1997 in which the time has flown by. Jayne and I moved here with two primary school aged children and a one year old. Now we have three grandsons that keep me busy.

Things have also changed dramatically on the farm in that time. Five irrigation reservoirs and a large investment in infrastructure have transformed the business as well as its cropping and labour force.

We have great team here at Nacton who work tirelessly to produce some of the best organic and conventional produce in the country.

I have had the privilege of working at Home Farm Nacton since 2000, I started as a Spray Operator and have worked up to my current position. I have a very supportive family around me, married to Kim with two great children.

I really enjoy the diverse variety of cropping which I look after at Nacton ranging from the main arable crops through to the more challenging ones such as sprouts/leeks and onions. Alongside competing in both conventional and organic markets.

We have a committed staff base who work hard alongside management in order to produce and maintain the standards which Home Farm (Nacton) prides itself on. I very much look forward to projects and new crop growing opportunities which we are planning for the future.

Things have moved on hugely since I first started working at Home Farm Nacton and I am proud of all that the whole team here has achieved during that time.

I had the privilege of growing up on a family run farm so therefore farming has always been a part of my life. I recently graduated from Easton and Otley College having completed a Degree in Agricultural Management and have always worked on farms from a young age. I am very excited about my role at Home Farm Nacton and look forward to learning and developing in such a diverse business.

I have worked in the office since February 2011, however I was out grading potatoes and onions in my teens! I work two days a week as I have three young boys that keep me busy the rest of the week. I enjoy my time at work; we have a cracking team which shows through the quality produce we produce all year around.

I’ve been working in the office for Home Farm Nacton since January 2008 but used to work on the back of the potato harvester grading potatoes and laying fleece during my school holidays as a teenager. The workload has definitely grown since that time but it’s still just as enjoyable. We have a great team here and it’s never a chore going to work.

I joined the team in 2016 and have found that no 2 days are the same at Home Farm. Its great to be able to work closely with all the customers and suppliers which makes the job so much more enjoyable. The team have been so welcoming and its great to work with people who have such passion for what they are doing.

Home Farm Nacton cropping

Over 50 years ago, our senior share holder, Gilliam Bence-Jones, came back from agriculture college full of enthusiasm for the flexibility that irrigation could provide. At the time, the technology was mostly confined to horticultural scale operations. Our farmland was seen as very poor and unproductive – Grade 3.

Could we put in the infrastructure to give ourselves new opportunities? Gill and her father, George, embarked on investing in three stream-fed irrigation ponds, pumps and underground mains to hydrants on the edge of some of the fields. Above ground, we had four and five inch aluminium pipes to lay to a network of three inch branches with sprinkler heads standing within the crops. All scaled up market garden stuff, and mostly aimed at potatoes, which were at the time our only crop with big potential losses or gains.

One of our steam filled ponds empties out onto a short ditch to the River Orwell estuary. Fresh (or ‘sweet’) water flowing over the mud at low tide creates an area rich in food sources for birdlife. We have recently put in a water metering weir which ensures that a guaranteed 4 litres per second of water always goes to the shore before we take any into our abstraction pond.

These individual, above ground systems are quite intensive to set up each growing season but can be used with dug-in drip tape to put water directly to the roots of the crop. This is a very efficient way of irrigating with minimal evaporation or runoff. It’s also a good way of getting water to a crop, which is covered with a sheet of fleece or has a very delicate foliage. Much of our ordinary irrigation, however, is done by reel irrigators. These huge drums have a butyl pipe that gradually wind back to themselves, pulling along a rain gun, or a wide wheel-mounted boom irrigator and covering a broad strip in a field.

We did once have access to an American-style pivot irrigator which is a huge steel arm, mounted on tractor wheels which slowly moves in an arc around a central pivot. Older ones just covered a large circular area and not many fields in Suffolk are round, but the latest ones now have extra ‘elbow’ type joints, electronically controlled, which can cope with fields with corners. The plus side on these permanent structures is that they take much less management hours to use (theoretically, as long as no one parks in their path!) but they are fixed and inflexible compared to our trailer-mounted reels and knock down systems.

We have now reached a point where we can irrigate most of our land and we can cross pump water from one area to another, rather like the National Grid. Although much of our equipment is automated (most of the reels have sim cards) is still takes up a tremendous amount of time every season, moving, setting up and checking, and often at unsociable hours. We now have reservoirs ranging from 7 million to 16 million gallons but we have been recently helping our farming partners to build new reservoirs of over 30 million and 50 million gallons. This all helps to smooth out the demand for water from times of shortage to months with over supply. The end result of all these years of investment is a business that grows over forty different types of crop for the consumer and creates over fifty jobs achieving it.

Final Fact

We are often asked why we irrigate when its already raining. We also noticed that its raining but if nature only puts on half the water the crops need, then this is an excellent time to ‘top up’ the amount while air moisture is high and evaporative waste is low.

Meet Bruce our ‘soil fertility manager’, our ‘top dressing technician’ or ‘chief muck and compost spreader’:

“Two main goals of applying muck and compost to the land are to increase the fertility and to condition the soil by adding organic matter. Another process is to change the PH, mostly by adding alkalis to acid soils. It is the addition of organic matter or humus which we are particular keen on. Low fertility additions, such as mushroom compost or council green waste compost can put a great deal of extra fibre into the soil, aiding water retention and slowing the release of nutrients. Not taking the straw after cereal crops also helps.”

- Mushroom compost

- Stable muck, fresh straw, horse poo and now days some wood chips too

- Digestate - liquid from the new generation power plants

- Chicken Manure - very strong in fertility, very hot and smelly

- Paper waste - not very fertile

- Brewers Waste - needs to be incorporated quickly

The “cluster” concept is encouraged by the government body “Natural England” to promote farmer led initiatives. These will (hopefully) eventually spread countrywide but are all individually small enough groups for the participants to know each other and keep the drive and enthusiasm which comes with your own pet project.

The other great advantage of the cluster concept is that the adjacent land holdings have an environment and habitat in common which can be improved and management techniques can be discovered and developed in specific ways that are appropriate to that locality alone.

This is particularly true to HFN land which borders on the Suffolk Sandlings and we reprint the ‘Sandling mission statement’ from our neighbouring facilitation group at the end of this article.

Our farmers groups are administrated in East Suffolk by Facilitator AJ Paul, who is an active farmer with a great enthusiasm for protecting the environment on his land and a particular interest in trees. He is assisted by Diane Ling, who has a vast knowledge and experience from working for Suffolk FWAG. We pay an annual subscription fee. One of the intentions of Natural England when it first started these groups was to encourage farmers into the latest versions of its Country Stewardship schemes. You will probably already be familiar with the long standing concept that farmers can gain some funding if they accept a regime which is supposed to be better for the environment, or perhaps some other socially worthy goal such as education or more public access. These schemes where funded in pounds by the UK government, (probably but the full answer seems complex) as opposed to the other major grant schemes available to farmers- “the BPS”, which is paid in euros from the EU, although of course the ultimate funding originally comes from our country’s subscription to the EU.

In the light of Brexit and Mr Goves recent preliminary proposal, (This article is written in January 2018), there can be no certainty to the future of grant funded nature conversation schemes for farmers in the long term.

The medium term seems to be foreseeable, but HFN has never seen these grants as essential or a lucrative form of diversified income. The amounts are not proportionally significant to our trading size and we feel a large commercial operation should never feel reliant on government grants.

However a marvellous potential of these cluster groups is that they can outlive the frequent changes to government funding and schemes. They bring together like minded neighbouring farmers and enable a continuous process of informed learning to help us to tailor our efforts to suit our own particular conditions.

The actual work done so far

We have planted 4.55 Hectares of land for either nectar for insect promotion or to provide a source of seed for birds during the winter months of scarcity.

Basic Pollen & Nectar Mix

Alsike Clover, birdsfoot trefoil, common vetch, red clover & yellow trefoil, black knapweed, musk mallow, oxeye daisy and sainfoin.

Butterfly & Bumblebee Mix

Birdsfoot trefoil Borage, Crimson Clover, phacelia and red clover

Universal Mix (Flea Beetle Treated)

Carbon, Coleor Kale, Fodder radish, gold of pleasure, Kings kale rape, mustard, utopia and vittasso brown mustard.

Campaign Mix South

Reed Millet, red and white millet, dwarf and intermediate sorghum, linseed, barley, wheat & triticale.

At present the seed costs £50 per hectare to drill. The facilitation group plan to have a small drill and a single team to achieve all the planting on its various members land.

The facilitation group organises regular informative meetings where members and other interested parties can hear talks from two or three imminent experts on specific environment subjects. As well as being interesting these help our members to understand what we should be trying to do to help their farmland environment and how to achieve it.

HFN together with some of its landlords such as Orwell Park Estate is trying to develop a hedgerow management and maintenance regime. We already try to not over flail cut certain hedges and banks or reduce some previously annual clipping to only every two years. We are now compiling a map and deciding on long term policies for each specific hedgerow to help us become consistent over the years in a sustainable programme which is good for wildlife. (One of the speakers at a previous facilitation group meeting was particularly interesting about the relationship between hedges and field margins)

In conclusion we include the Sandlands mission statement;

Sandlands mission statement

To facilitate cooperation to sustainably enhance the Sandlands landscape, its environment, habitats & species, beyond what is achievable when land holdings are managed in isolation.

The Vision

To deliver the objectives of The Countryside Stewardship Scheme. To nurture a better understanding of the wildlife and habitats important to The Sandlands

To encourage a better understanding of the issues affecting the environment and wildlife on The Sandlands.

To demonstrate best practice in wildlife management as an integral part of modern farming.

To demonstrate best farming practices to protect soil, water and air

To restore areas of under managed heathland, grassland, open sandy areas and other habitats important to the Sandlands.

To improve watercourse management to help reduce siltation and improve the riparian environment

To connect habitats via corridors or stepping stones to all populations to spread.

To forge links with individuals and organisations with an interest in The Sandlands.

‘On the ground’ (for first two years)

Combine farming, soil protection and wildlife management through the use of green cover crops, Wild bird seed mixtures and nectar plots. Look at ways of linking wildlife corridors across farms.

Use traditional defences and soft approaches to alleviate flood risk, improve soil structure and restore the natural functions of our watercourses. (Working with the EA)

Use FEP’s and baseline surveys to identify what we have in The Sandlands and the feasibility of increasing or restoring key species. Working with the Suffolk Biological Records office to produce a group only mapping system that can be used to record flora and fauna found on the farms.

Coordinate a Grey Partridge project with the combined efforts of the gamekeepers and the GWCT.

‘There is more fresh water pumped out to sea by drainage pumps than the whole of the UK uses for irrigation.’ This bombshell of a fact was once mentioned by Tim Darby at an ESWAG presentation in Home Farm Nacton office.

We have been a member of ESWAG (East Suffolk Water Abstractors Group) for a long time but this meeting was to discuss a new and exciting possible water source

Anyone who knows Home Farm, or just reads our website, will know that water is the key ingredient to our operation. It is the one thing that makes vegetable production possible on our light soil in the low rainfall East Suffolk Sandlings. Last year (2018) was a near perfect demonstration of the importance of irrigation, without water and hard work and equipment, our crops would have failed for sure.

And as you’re no doubt aware, the source of all these millions of gallons of water, upon which farms like Home Farm so absolutely depend, is a natural resource of great importance and value. Most of our farms irrigation supply comes from streams which flow across our land into the salt water estuary’s. Some of our water comes from the two aquifers that lie below us, the crag or chalk.

Agriculture is heavily regulated and will be restricted in its future water use. Household supplies and industry compete for the same resource and the water that flows in streams is also of great importance to wildlife.

So it was most exciting when we started to hear about a possible scheme to use land drainage water from the Falkenham & Felixstowe Ferry marshes around the Kingsfleet. In the past, it was an arbituary rule that water pumped by the drainage board had to go over the sea wall into the estuary. A rule set in stone and because of the volumes involved, is also damaging to the mud flats. But in recent years, this kind of inflexible approach has been questioned more and more, especially by farmers beside drainage pumps with irrigation requirements of their crops. A few years ago, Jane Burch, a local counsellor took up this matter and has continued to work hard for the project to succeed ever since.

From a farmer point of view its mostly the cost of 11.8 km pipeline to bring the water to each involved farm. The Environment Agency then decided that it will impose an extraction license and a fee. And in order to turn all of this expense into delivered water at an acceptable cost, (Farmers tend to compare irrigation costs in the old fashioned formula of ‘pounds per acre inch) a grant has been applied for. Only then can the use of this water source become viable. The grant is from the unlikely confines of the EU and is from a fund which was intended to encourage the replenishing of aquafers bordering the middle sea. This means any EU countries on the edge of the North Sea and English Channel. The grant will also cover 3 different schemes in Holland, Belgium and Suffolk, joining in a grant application to develop schemes to put fresh water back into aquafers, to reverse the process of saline water ingress.

So if we can be the driving force behind this scheme, then we feel very happy to be leading the way in what is, put very simply, a future insurance of our continued food supplies and water supplies too.

Home Farm Nacton currently farms 405 acres, 164 hectares organically. This is only a part of our overall activity which currently covers about 4000 acres of land.

So why do we farm some land conventionally and some organically? Why don’t we farm all our land organically?

In order to understand the present position for our organic operation its necessary to understand the history of agriculture in previous years.

First, we should define organic farming. DEFRA states - ‘Organic food is the product of a farming system which avoids the use of man-made fertilisers, pesticides, growth regulators and livestock feed additives. Irradiation and the use of genetically modified organisms (GMOs) or products produced from or by GMOs are generally prohibited by organic legislation. ‘Organic agriculture is a systems approach to production that is working towards environmentally, socially and economically sustainable production. Instead, the agricultural systems rely on crop rotation, animal and plant manures, some hand weeding and biological pest control’

However, the public perception of organically grown produce is that ‘they are better than conventional’ which isn’t an entirely clear concept. The other general public observation would probably be that ‘organic farming is better for the countryside because it uses no chemicals and bad stuff’, but that also isn’t a black and white scientific fact. So we had better examine the evidence.

The Soil Association, which is the most well-known organic organisation, was set up in 1946 by Lady Eve Balfour and friends at Haughley in Suffolk. The date 1946 is significant, we had just been through the blockades of the second world war, which had driven agriculture to desperately increase yields, with all the knowledge of science and technology of that era being stringently applied. If farmers didn’t comply with all these changes and upgrades their land could be taken away.

So, in 1946 Sir Clavering Fison and Henry Ford were seen as agricultural heroes of the war. But as we often find with new processes there are often unexpected side effects and long-term problems. Traditional farming in the British Isles had evolved over the centuries and hadn’t always rushed to adopt these new methods. Farmers tend to be suspicious of change and it could be said that the old ways were tried and tested in a way that we now call ‘sustainable’.

Lady Eve and friends with a Fordson tractor

But new modern ways of farming enabled an intensification of farming. Much higher yields could be obtained from existing farms and land that could not be ploughed and cultivated before could now be brought into production. British farming had languished in an economic slump which reached back 100 years to the repeal of the corn laws and this might have been why it was slow to adapt new ways until the inducements of the war.

After the war the potential for profits, coupled with the ‘can do’ attitude of returning sons and daughters brought about a real revolution in farming in the UK. Conventional farming was marching ahead with spectacular results and the next 30 years were to transform the British farming landscape, regardless of the suspicions of traditionalists.

Meanwhile the organic movement steadily gained pace as a viable alternative to all this science and sprays. Its processes and theory took shape, also alternative bodies to the soil association were founded. The word ‘Organic’ began to mean something in the English language which was linked to the crops and produce. For a long time, it wasn’t accepted by the main stream, but it was gathering momentum.

Let us now talk specifically about Home Farm Nacton.

By the new centuries start in 2000, we had been moving in to the wonderful world of large-scale vegetable production for almost 20 years. Our light sandy soils and our early adoption of irrigation had helped us to evolve from arable farming to become one of the major vegetable growers outside the Fens, with good links to the supply chain which feeds most of the country through modern supermarkets.

We had, like most farms, seen a drastic reduction in our workforce when we were entirely arable. All the aforementioned advances in technology, although expensive to purchase, are ultimately about saving money and enabling farmers to reduce costs and lead to economies of scale. Also the famous East Anglian ‘Prairies’ were on the rise. Fields of 80 acres and over enables mechanised farming. But by 2000 we had begun to reverse some of these trends with an increase to our workforce on the back of better returns from the new vegetable crops.

We began to get increasing demands from our customers for organic versions of what we already grew for them. Unlike purely ethically motivated organic producers we could see that it was an emerging market with commercial opportunities, which we were almost uniquely placed to provide for with our track record of large-scale production to auditable quality which the supermarket buyers expected.

We converted our first land in the 1990s and after the two years conditioning period began to see very good yields. We already had experience of seasonal field workers from other areas of England and also from the recently opened countries of eastern Europe. Mostly our labour was provided by agency labour but we began to develop relationships with some of the newly arrived people which lead to an in-house team of fully employed European workers at Home Farm Nacton

The need for labour had come full circle from reductions of the post war technological advances and also now the minimum wage legislation began to influence what farmers had to pay (although some would say that the laws of supply and demand would always lead to an actual wage increase). The economies of the Eastern European nations were also beginning to improve, making the difference in pay scales less dramatic.

We have come through the economic downturn of 2008 which revealed that British consumers thought of organic vegetables as a luxury they could cut back on during financial hardship. (This wasn’t so much the case on mainland Europe where the organic or ‘biological’ choice is more of a lifestyle, like vegetarianism).

Organic Leeks being hand harvested

Organic Leeks, not a weed in sight

In the last 20 years we have grown many different crops on our organic converted fields (which are listed at the end of this article). In the last few years, a new “middle way” has emerged and is gaining in popularity around the world. This system recognises the importance of soil health and how we can improve it. The system is known by a number of different names: Regenerative Agriculture, Conservation Farming or “No till” Farming.

One of the main pillars of the system is to stop ploughing the land and reduce cultivations or keep tillage to a minimum. Cultivating the land causes the following problems:

(1) It destroys the soil microbes in the soil releasing carbon dioxide into the atmosphere

(2) It reduces the soils organic matter.

(3) It causes an increase in soil erosion.

Regenerative Agriculture allows us to produce healthy sustainable food at a price everyone can afford.

At Home Farm Nacton we have always treasured and cared for our soil quality. Naturally light and sandy soils are helped with our continuous program of adding various natural improvements, as described in a previous article in this series ‘soil organic matter at Home Farm Nacton’ We are also very careful to run a cautious crop rotation program but, is this new approach to farming just a fad, or something we should seriously consider?

But news continued to reach us that others were being influenced towards conservation farming. One particularly startling development was the Danish Parliament who gave up promoting organic farming as an ideal and now say that conservation farming is preferable. The Danish Parliament has a strong Green Party presence, presumably the Danish Green Party prioritise what is actually the best way to produce food for humans without damaging the land.

Another factor may be that in order to support organic farming organic crops usually have to command a higher price. Because the Green Party’s usually have a socialist ethos, they don’t want to encourage anything that is seen to be only for the elitist premium market. And yet another factor in their decision could be the idea that Carbon Capturing is overruling all other environmental considerations. ‘No till’ captures much more Carbon than other farming methods.

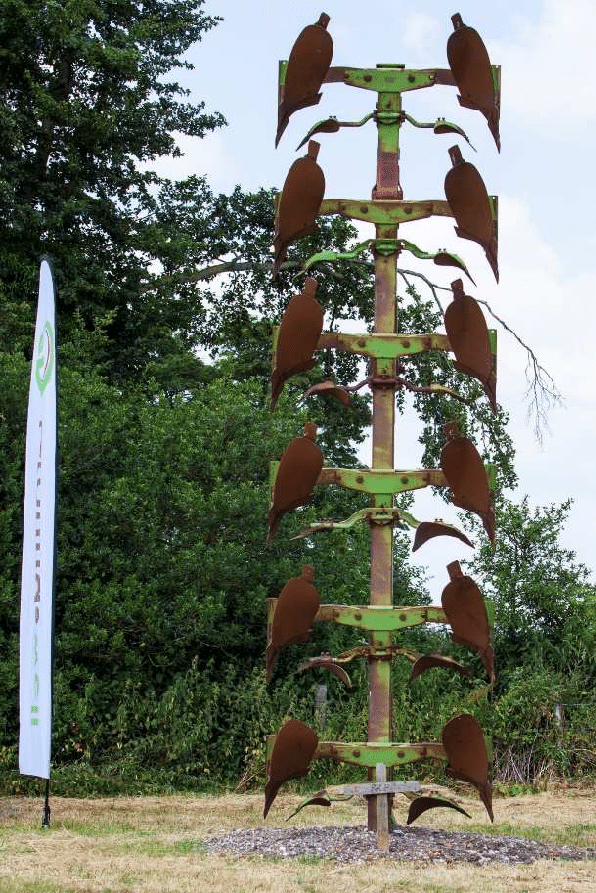

The RIP plough monument at the Groundswell show at

Lannock Manor Farm, Hertfordshire

Photo by Alex Cherry

We are considering strip tilling some crops, which we have recently seen in use in Norfolk. With our consultants help we are doing research within our soil types at a microscopic level. We have also had surveys done for detailed soil mapping on some fields.

As for the future of organic farming at Home Farm, we have looked into many other potential organic crops. William Hudson from Hodmedod’s has worked with us to develop various combinable crops less reliant on hand labour. We have also in recent years tried growing organic feed crops for the organic dairy business. But often new products have very small and undeveloped markets and a lot of test crops grow well for one year but don’t get planted again.

We also try to keep abreast of developments in robotics, because small robots when available in quantity could well be the answer to the eternal weed problem that organic farming particularly suffers from.

In conclusion we do not accept the idea that conventional agriculture is intrinsically bad or that organic agriculture is all good. Conventional agriculture has become in recent years more diverse and less intense and now has far fewer pesticides and herbicides available to use. Its effects on the environment, with factors such as fertiliser run off or hedgerow management, is closely regulated and in practise conventional will continue to grow closer to organic farming.

Conservation agriculture shows us that there are other ways to achieve success through re thinking the ”yield versus costs” equation.

Organic farming has led the way for a major market demand for alternative grown produce and prompted public interest in more thoughtful ways of farming.

So, in our continuing mission to grow large scale quantities of diverse produce to feed the nations tables, here at Home Farm Nacton we embrace all of these different methods of operating, and feel there is no particular conflict between them.

Organic Crops grown by Home Farm Nacton

- Sprouts

- Red, Savoy, Pointed Cabbages

- Cauliflower, Romanescu, January king

- Broccoli, Purple Sprouting Broccoli

- Leeks

- Brown & Red Onions

- Vining Peas

- Potatoes

- Population Wheat

- Spring Barley

- Red Beet

- Sugar Beet

- Fodder Beet

- Spinach

- Sweetcorn

- Quinoa

- Celery

- Kohl-Rabi

- Celeriac

- Asparagus

- Buckwheat

- Beans

- Green & Black Kale

- Golden Beet

- Candy Beet

The kind of mechanised hoe which saves labour costs in organic farming

This is a machine built in Denmark by Agri Intelli and is the first of its kind in the UK, although the 30th in Europe.

Because of this trailblazing, pioneering factor there has been quite a lot of publicity, encouraged by the farming press, but spilling over into the mainstream UK news too.

ROBOTTI in action

Its two boxes on four wheels, with a 3-point linkage about the size of the equipment worked by an old Fordson or Massey Ferguson size tractor.

Why have we brought it?

Hopefully not to just play the publicity game, - that we were the first to have one, and neither to replace our employees or agency temporary workers. One memorable quote made by one of our team on the launch day was ‘they know it’s replacing the jobs no one wants to do’.

You can see much more detailed news about the Robotti on the Agrointelli and Fram Farmers websites.

What you may not realise at first look is that it isn’t actually anything really new.

The words ‘diesel, hydraulics, GPS, sim card and online’ are all ones we’ve heard before. It’s just the application in this machine which is new.

Is HFN’s new machine actually a Robot? Didn’t we expect Robots to be metal men capable of replacing Humans? Plenty of science fiction scenarios provide just such a vision of the future.

In one sci-fi short story I remember reading at school, a loyal employee is made redundant at his job, replaced by a Robot. He sadly reflects while he walks home, but is cheered up by the thought of his wife’s wonderful cooking. But when he gets back the Robot is already there, sitting at the table, eating his dinner.

The history of agriculture has been a series of technological advances for centuries. The mechanisms that control the flow of wheat into grind stones in windmills, as the strength of the wind rises and falls, to ensure a uniformly milled flour is produced, could be judged as some of the first ‘autonomous automations’.

The advances of the ‘Industrial Revolution’ provoked the angry reaction of the Luddites to the direct replacement of their jobs by machines, but it didn’t actually affect the level of overall employment at the time.

In more recent times, post second world war, the ‘Green Revolution’, (that’s the 1960s one, not the latest use of that much over referred to colour), led to a loss of jobs on the land, as big machines and agri-chemistry took over in large scale fields.

So, a Robotti could just be seen as merely a continuation of the long-term trend to mechanisation in agriculture, but let’s consider what’s on the market and to a certain extent already out there in the fields already. I’m writing in 2021. At one end of the spectrum you can find driverless versions of large tractors already being sold by the existing major tractor manufacturers. They tend to be set at working in big, prairie like fields and the red, blue, green and crimson major tractor brands all have them already available.

The one company which seems to be most advanced in offering a wide range of automated equipment to farmers is John Deere. It’s worth having a look at their online material, although some of it may be that old sci fi staple, imagined machines of the future that are actually grounded in the limitations of the present, such as an electric tractor which in order to get the necessary horsepower usually provided by large diesel engines, relies on mains electricity and a huge reel of power cable. They also have a drone so big that it looks like it could compete with a Huey Helicopter.

There are banks of autonomous multi headed hoes mounted behind a tractor for dealing with salad crops which claim to be operating in a robotic fashion. Up in the skies various drones are available, some of which are autonomous, especially for crop spraying duties. This can be a key part of the Micro Management system of dealing with each crop in a detailed way idealised for each square meter of a field.

These things can be found with a little online research of ‘agricultural robots’ or other similar search titles. But are they really Robots? When does farm mechanisation become robots? I’ve possibly missed out on plenty of other farm robots which may already be operating and definitely exist on the drawing boards or CAD screens of inventors everywhere.

What will be in the fields of the future? Who can tell what will catch on and what’s a white elephant? But will we be replicating all human farmers and field workers anytime ever? There’s another old sci-fi story called ‘But who can replace a man?’ by Brian W. Aldis. I’ll spoil it for you, here are the last two lines of that story, when the machines encounter one of the surviving humans- ‘get me food’ he croaked. ‘Yes master’ said the machines ‘immediately’.

A barbecue meal and a few chairs had been provided by the Hydrocycle Company beside their new pumphouse and when everyone was gathered John Patrick made a short speech. He pointed out all the various people in case they didn’t know each other, and thanked them for all the things that had been achieved, all the obstacles overcome to reach this point of happy celebrations.

The party then continued with a great dialogue between all of the people involved and we must have presented a puzzling picture to the passing walkers and cyclists on the sea wall.

It’s a lovely place to visit with the most amazing long-distance views, the same could almost be said about the successful completion of the first ever recycled drainage water irrigation scheme and combined aquifer recharge experiment. A nice place to be.